The great explorer of the truth, the master-builder of human happiness no one rejects dislikes avoids pleasure itself because it is pleasure but because know who do not those how to pursue pleasures rationally encounter consequences that are extremely painful desires to obtain.

Read More

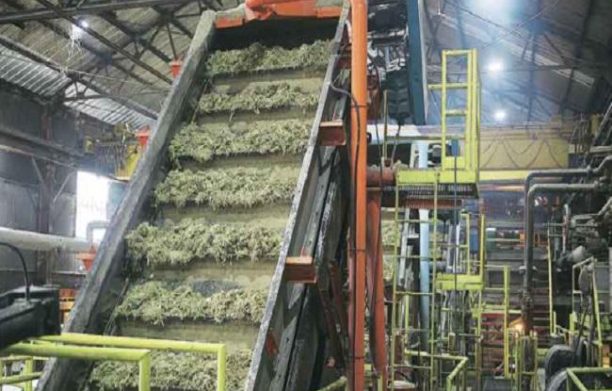

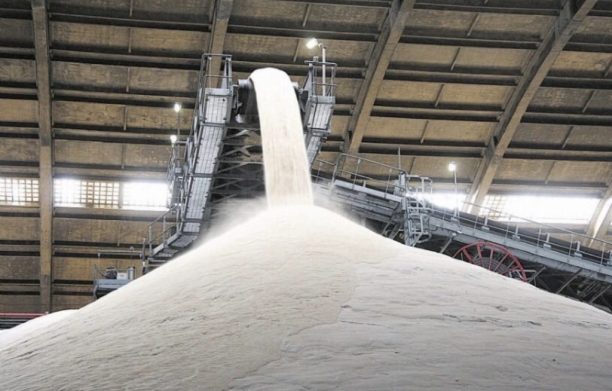

White Sugar Sulphur Plant

Microtech Engineers specializes in designing and manufacturing White Sugar Sulphur Plants tailored for efficient, high-quality sugar production. These plants utilize sulfur-based purification to remove impurities, ensuring the final product meets international standards for brightness, texture, and purity. Our systems integrate advanced filtration and evaporation technologies to optimize energy consumption and minimize waste, making them ideal for large-scale sugar mills. By automating key processes like sulfur dosing and crystallization, we ensure consistent output while reducing manual intervention. Microtech Engineers plants are engineered for durability and compliance with global food safety regulations, catering to industries that demand premium-grade white sugar for beverages, confectionery, and packaged foods. Partner with us for turnkey solutions that enhance productivity, reduce operational costs, and align with sustainable manufacturing practices.

White Sugar Non-Sulphur Plant

Khandsari Plant

Refined Sugar Plant

Jaggery Powder Plant

Jaggery Cake Plant