The great explorer of the truth, the master-builder of human happiness no one rejects dislikes avoids pleasure itself because it is pleasure but because know who do not those how to pursue pleasures rationally encounter consequences that are extremely painful desires to obtain.

Read More

Microtech Engineers India

Specialized Equipment

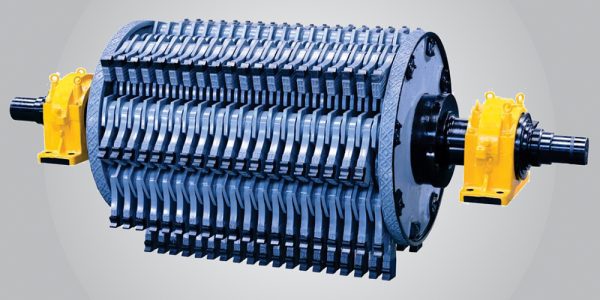

Milling Tandem

Microtech Engineers designs robust Milling Tandems to maximize sugarcane juice extraction with precision. Our tandems feature heavy-duty rollers, optimized pressure settings, and automated feed systems to crush sugarcane efficiently, ensuring high juice yield and minimal fiber loss. Built for durability, these systems reduce downtime and maintenance costs, making them ideal for large-scale sugar mills. Customizable configurations cater to varying capacities, while energy-efficient motors align with sustainable operations. Trust Microtech Engineers for milling solutions that boost productivity and profitability.

Tubular Concentrator

The Tubular Concentrator by Microtech Engineers revolutionizes juice concentration with its compact, high-efficiency design. Using advanced heat exchange technology, it rapidly evaporates excess water from sugarcane juice, retaining natural sugars and nutrients. Ideal for medium to large plants, our concentrators reduce energy consumption by 30% compared to traditional systems. Stainless-steel construction ensures hygiene and longevity, while automated controls guarantee consistent results. Partner with Microtech Engineers for eco-friendly, cost-effective concentration solutions.

Open Pan

Microtech Engineers offers Open Pan Systems for traditional jaggery and khandsari production, modernized for today’s demands. Our pans feature reinforced steel construction, uniform heat distribution, and easy tilting mechanisms to streamline boiling and crystallization. Designed for small-scale producers, these systems preserve the authentic flavor and nutrients of sugarcane while reducing fuel consumption by 25%. Affordable and easy to operate, Microtech Engineers’ Open Pans empower rural entrepreneurs to scale production sustainably.

Clarifier

Enhance juice purity with Microtech Engineers’ Clarifiers, engineered to remove impurities like mud, fibers, and colloidal particles from sugarcane juice. Our clarifiers use gravity settling, flocculation, and automated sludge removal to deliver crystal-clear juice, optimizing downstream processes. Built with corrosion-resistant materials and smart sensors, they ensure minimal manual intervention and compliance with food safety standards. Choose Microtech Engineers for reliable clarification that elevates sugar quality and operational efficiency.

Fibrizer

Microtech Engineers’ Fibrizers transform sugarcane bagasse into fine, usable fiber for paper, fuel, or composite materials. Equipped with high-speed blades and adjustable mesh screens, our machines ensure uniform fiber size while reducing energy use by 20%. Compact and low-maintenance, these systems help mills monetize waste sustainably. Partner with Microtech Engineers to turn byproducts into profitable resources.

Slat Conveyer

Microtech Engineers’ Slat Conveyers excel in handling bulky or abrasive materials like bagasse and ash. Built with interlocking steel slats and heavy-duty chains, these conveyers resist wear and tear even in harsh environments. Customizable inclines, automated lubrication, and overload protection ensure minimal downtime and maximum reliability. Ideal for sugar mills and biomass plants, our slat conveyers deliver unmatched durability and performance.